Have you ever asked yourself how the metal parts you use daily were created and how they became the piece you want? You must have come across products from rolling mill machines in your daily life, even though sometimes you don’t even know that the product you are using is made in a rolling mill machine. If you want to know about the rolling mill machine, its types, and the products it produces, don’t miss this article.

What you read in this article ...

What is a Rolling mill machine?

Custom metal products are used almost in most industries. Products that are made of different types of metal in different shapes. Most of these products are made with a rolling mill machine. Parts of heavy industries, parts of cars, and even mobile phones, were produced in rolling mill machines. But what is the work of the rolling mill machine? A rolling machine is a machine in which the metal passes through a series of rollers, and its thickness is uniformly reduced. It is formed into metal sheets with flat, round, conical, and curved sections of different and customized sizes. Different types of rolling are chosen based on the process the metal needs to go through for your custom product. But before we discuss the types of rolling mill machines, it is better to see what products enter the rolling mill machine and what products are created from them. Ingot is a raw product that enters the rolling machine. This piece is often produced by casting and comes out of the mold with various defects. The ingot enters the rolling mill machine, and the following products are created from it.

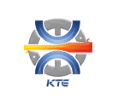

The primary products of the rolling mill machine

1. Bloom: The first output of the ingot from the rolling process is called bloom. The cross-section of the bloom is more than 230 square centimeters.

2. Billet: The product is obtained by further rolling of Bloom, having an area of Cross-section greater than 1600 mm2

Slab: It is a hot Rolled Ingot with a Cross-section area greater than 100 cm2 and Width>=2*thickness.

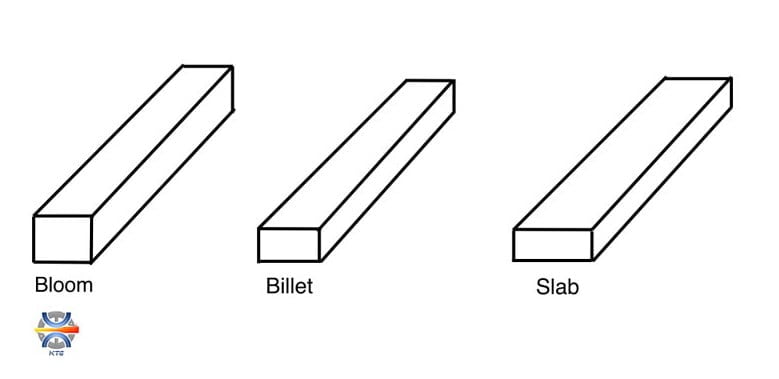

Secondary products of the rolling mill machine

1. Plate: It is a Mill product with a thickness of more than 6 mm.

2. Sheet: It is a Mill product, with a thickness of less than 6 mm and a width greater than 600 mm.

3. Strip: It is a Mill product with a thickness of less than 6 mm and a width of less than 600 mm.

Some of the finished products of the rolling mill machine

4. Foil: It is a thin strip with a width of 300 mm and a maximum thickness of 1.5 mm.

5. Bar: It is a Uniform circular cross-section Object in the form of a Cylinder.

6. Wire: It is a bar with a small area of cross-section, which may go up to 9.5 mm.

7. Beam: Which are produced in the form of I U T H in different lengths and dimensions

8. structural profile: Types of structural sections such as corner, can and profile, etc. They are used in construction

Types of rolling mill machines

The type of metal and the final product specifications determine what kind of rolling mill to use. Different rolling machines differ in the number of rollers and their arrangement type, which are selected based on the final product. Some of the main types of rolling mill machines are :

1. Two-high rolling mill

It consists of two High stands and two rolls placed exactly one over the Other. In this type of Rolling Mill, the Rollers rotates in Opposite direction, and their direction changes after each Metal pass. The Metal (Ingot) is passed continuously, and approximately 25-30 passes are required to convert Ingot to Bloom. This method, which is a type of cold rolling, is more suitable for soft metals such as copper and lead, but it cannot make the metal as thin as the three-high rolling mill.

2. Three-high rolling mills:

In three high-rolling mills, Rollers are present in the same vertical plane. The Top and bottom roller rotate in the same direction, and the middle roller rotates in the Opposite Direction. In this type of Rolling mill, the Direction of the drive is not changed after each pass, so It is more Productive and more manageable than the two-High Rolling Mill. It is often used to produce coating materials and is excellent for metals such as steel, aluminum, and stainless steel. But if a very thin thickness is needed, it is better to use a four-roller rolling.

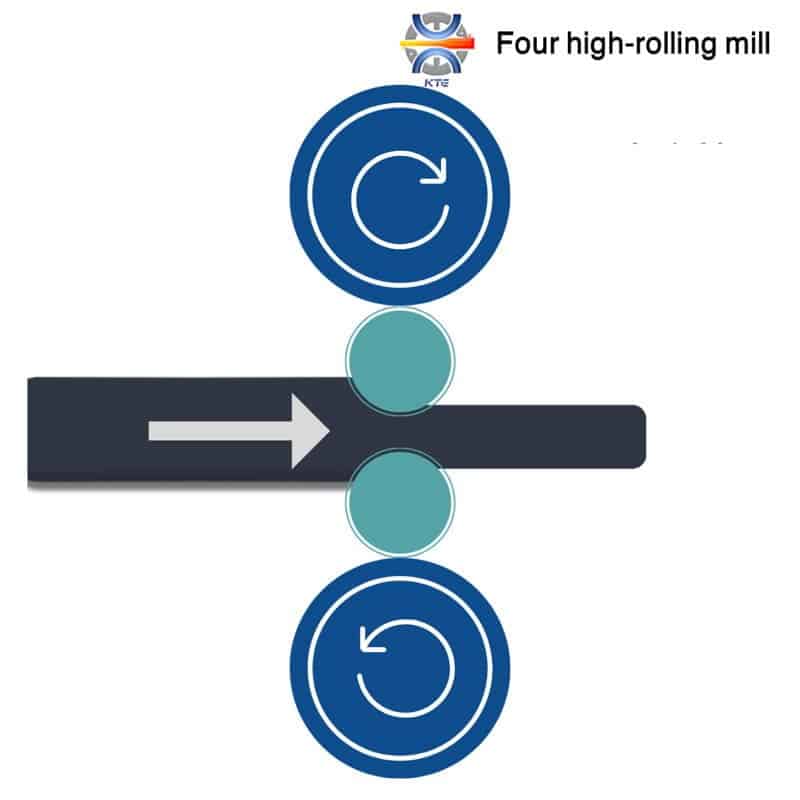

3. Four- high rolling mill:

It consists of two backup and two Working rollers, arranged One over the Other in the same Vertical Plane. The Diameter of the Backup rollers is always greater than the Working rollers. This type of roller is mainly used in Sheet Rolling. The Two Working Rollers of small diameters are used to reduce the power demands, but it increases the chance of bending of working rollers and, as a result, non-uniform compression of sheets. This is why we use Backup rollers to reduce the bending of Working rollers. This rolling mill is indeed more expensive than other models; still, it can deliver very thin sheets and is used more in industries such as aerospace and military, which often require precise metalwork.

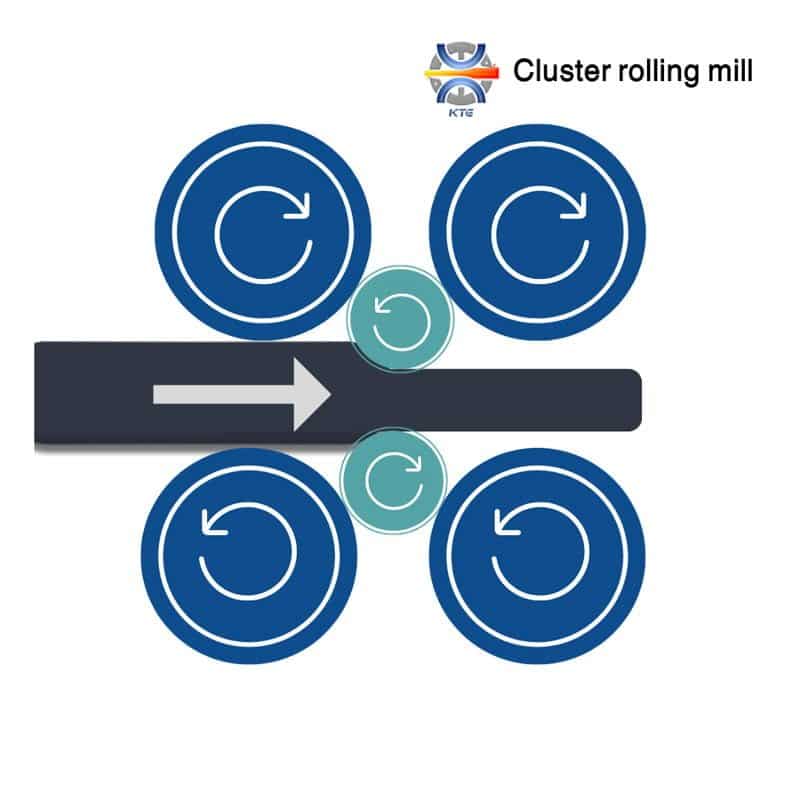

4. Cluster rolling mill:

Cluster rolling consists of two engaging rollers and two or more supporting rollers. The number of support rollers depends on the power required for rolling. In this machine, a group of metals are lined up one behind the other for thinning. Cluster rolling works with considerable precision, and advanced technologies such as automatic gauge control and dynamic power adjustment are used in its construction and are usually used in cold rolling.

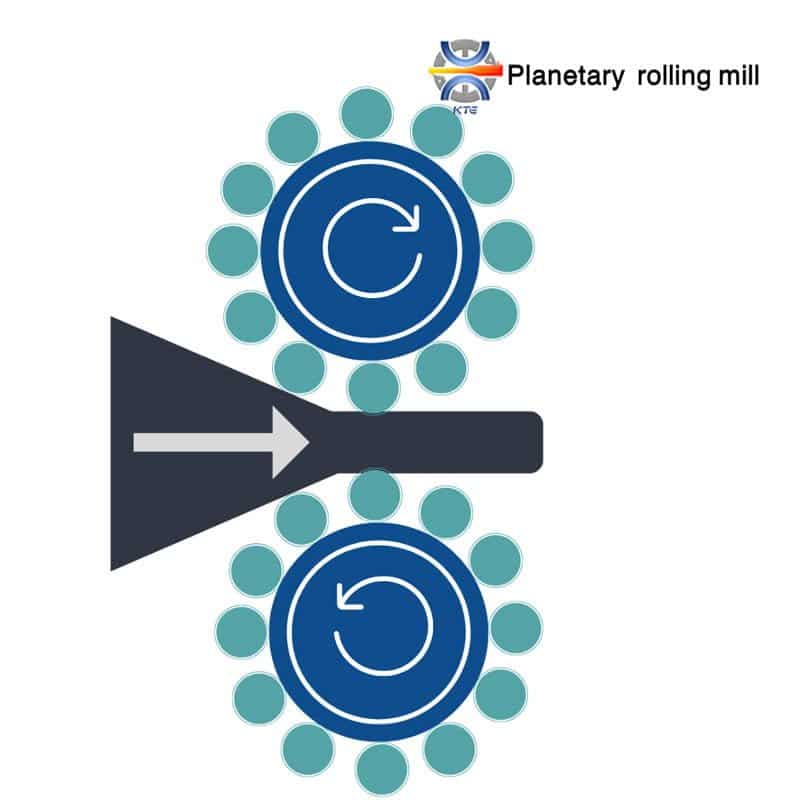

5. Planetary rolling mill:

This machine is mainly used for rolling raw metal rolls. The output of this rolling is lower than continuous rolling and more than rolling with two or three high rollers, and it is mainly used for metals that have less flexibility.

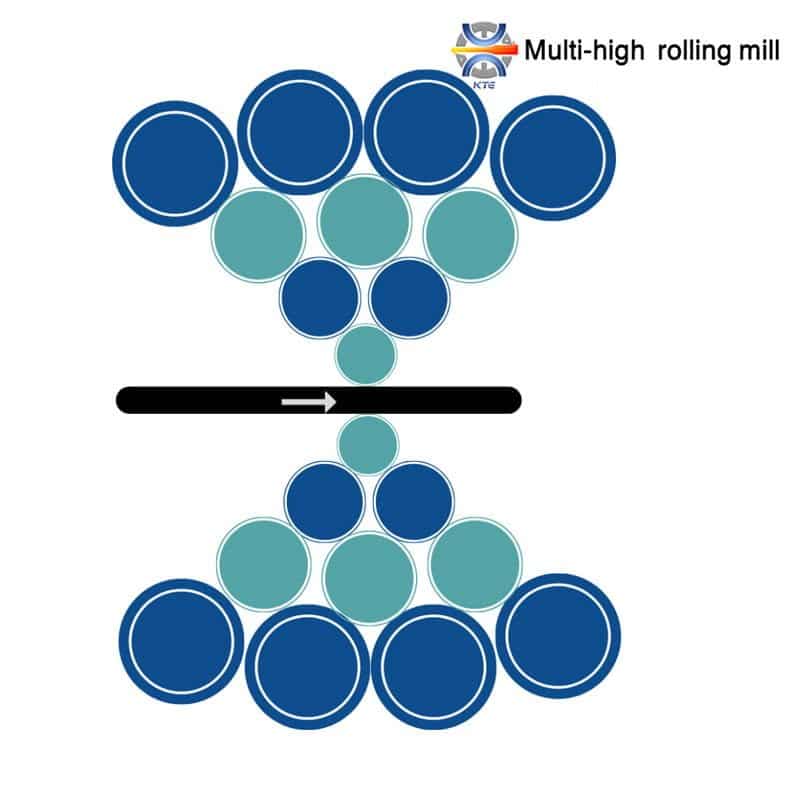

6. Multi-high rolling mill :

It consists of two small diameters of working rollers, an intermediate row of driving rolls, and a row of Backup rollers. The arrangement is made in such a way that the whole system achieves exceptional rigidity. Multi-High Rolling mills are used for making a sheet of minimal thickness.

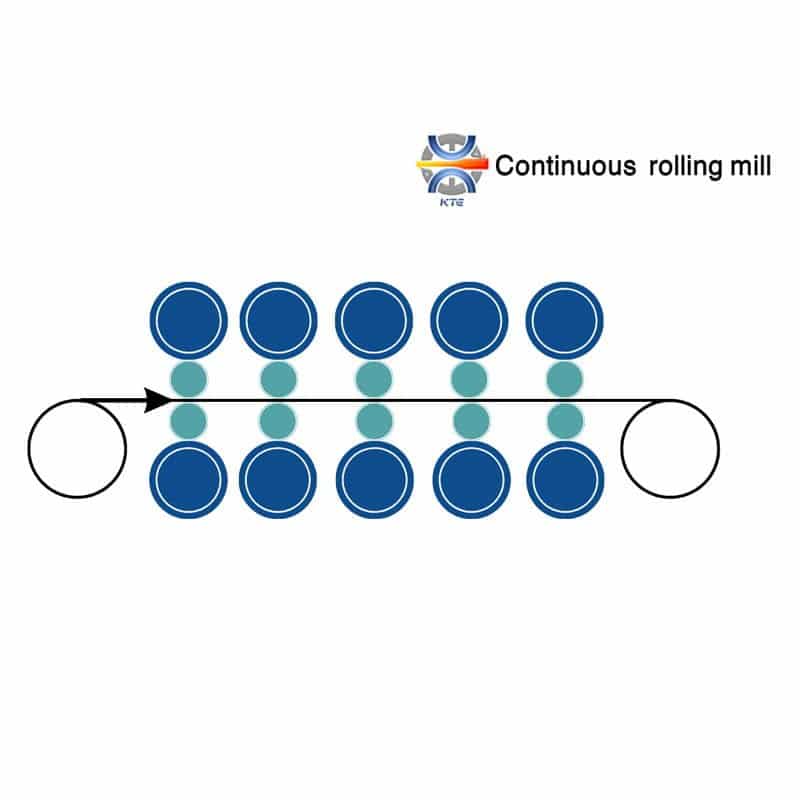

7. Continuous rolling mill:

It is a device in which the sheet passes through several rolls and becomes thinner.

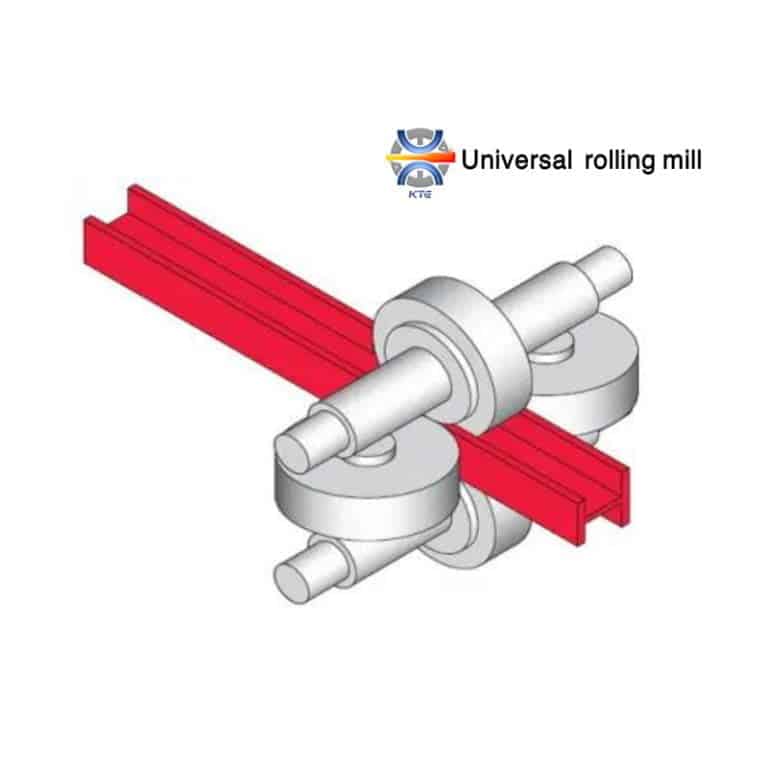

8. Universal rolling mill:

In this machine, there are two horizontal rollers and two vertical rollers, the vertical rollers are mounted on the horizontal rollers, and it is often used to produce bloom from ingots and produce an H beam.

Working steps of the rolling machine to produce the final product

1. Primary rolling

It is the Primary stage of Thickness reduction, in which Ingot is changed into simple stock members like bloom and slab. This process modifies the structure of the metal, improves its mechanical properties, and removes internal defects.

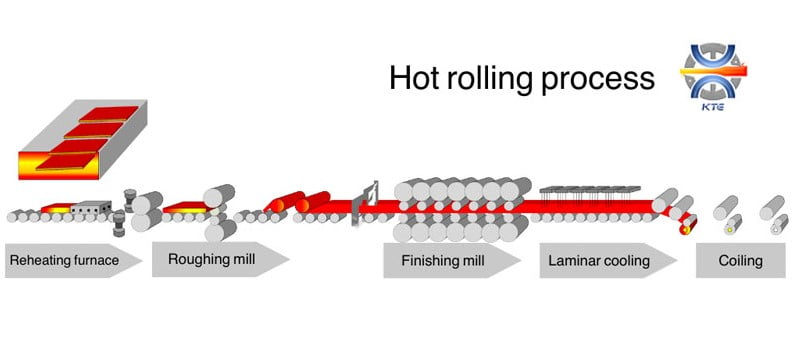

2. Hot rolling

In this process, the temperature is higher than the metal’s recrystallization temperature and must be set uniformly in all areas of the part. Compared to the recrystallization temperature, this higher temperature makes the steel more malleable. In hot rolling, blooms, and slabs are placed in the rolling machine and are transformed into plates, sheets, bars, and other secondary forms by generating heat. Finally, the parts cool and shrink. Because this shrinkage makes it impossible to measure the final shape accurately, hot rolling is unsuitable for items requiring precise dimensions.

Hot rolling products are primarily used as rebars in welding operations, construction, and making rails and beams.

Advantages of hot rolling:

- Hot-rolled products have high formability due to increasing temperature.

- After rolling, the parts are cooled at a suitable temperature, which prevents them from becoming brittle or stiff.

- Hot-rolled parts require fewer processes and are sold at a lower price than cold-rolled parts.

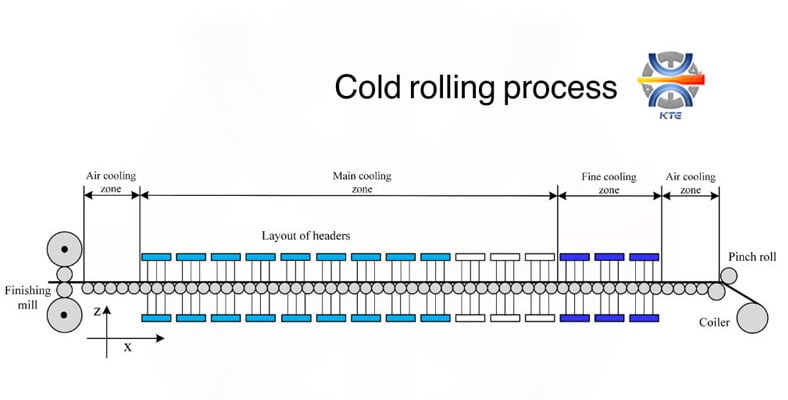

3. Cold rolling

If the temperature in the rolling process is lower than the metal’s recrystallization temperature, it is called cold rolling. When the parts need more precision, the cold rolling process is done on the pieces after the hot rolling process. The hot rolled products are placed in the cold rolling machine so that more work is done on them and the product is made with more quality and accuracy. Because the temperature of cold rolling is lower than that of recrystallization, the product’s surface quality also increases. In the products of this rolling, the deformation is done without using heat, and generally, mechanical stress is used instead of heat to change the structure of the metal. Cold rolling machines for producing a wide range of products, including sheet metal used for automotive and aerospace applications, electrical components, and structural steel. They are also used to make unique products such as stainless steel and aluminum alloy.

Advantages of cold rolling:

- Good appearance and accurate dimensions

- Easy transportation

- High tolerance and resistance

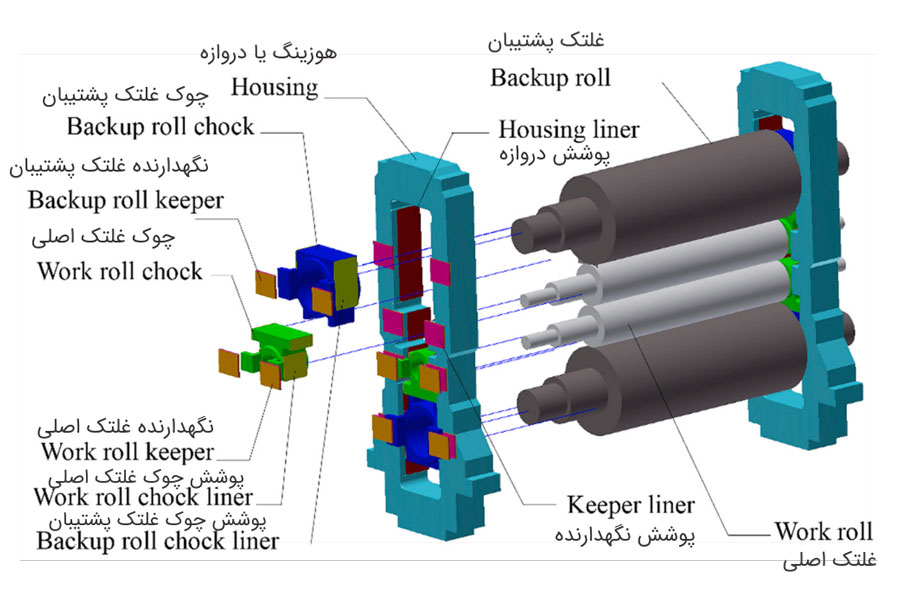

Rolling mill machine parts:

The rolling machine includes a rack in which the following parts or components are placed:

Housing: the rollers are placed inside this rack.

Rollers: the main components of the rolling mill machine for making metal sheets.

Bearings: supports to reduce friction are usually used to prevent energy waste and minimize damage to moving parts during work.

Chock: a container that protects the bearing and keeps it in the proper position.

Why choose Kian Tarash Spadana Company to supply rolling mill machine parts for you?

It is necessary to design and build modern and high-quality equipment to have a rolling mill machine with high economic efficiency and a reliable investment return. By using the latest equipment, a professional team, and long experience in this field, Kian Tarash Spadana company can contribute to the operation of the machine by manufacturing and producing all kinds of rolling mill machine parts. We are proud to meet customers’ needs in manufacturing and designing rollers, chokes, bearings, housings, and all rolling mill machine parts as soon as possible and with the best quality. The equipment of this company will reduce costs and improve your business.

For more information and price inquiries, click the button below to contact you as soon as possible.